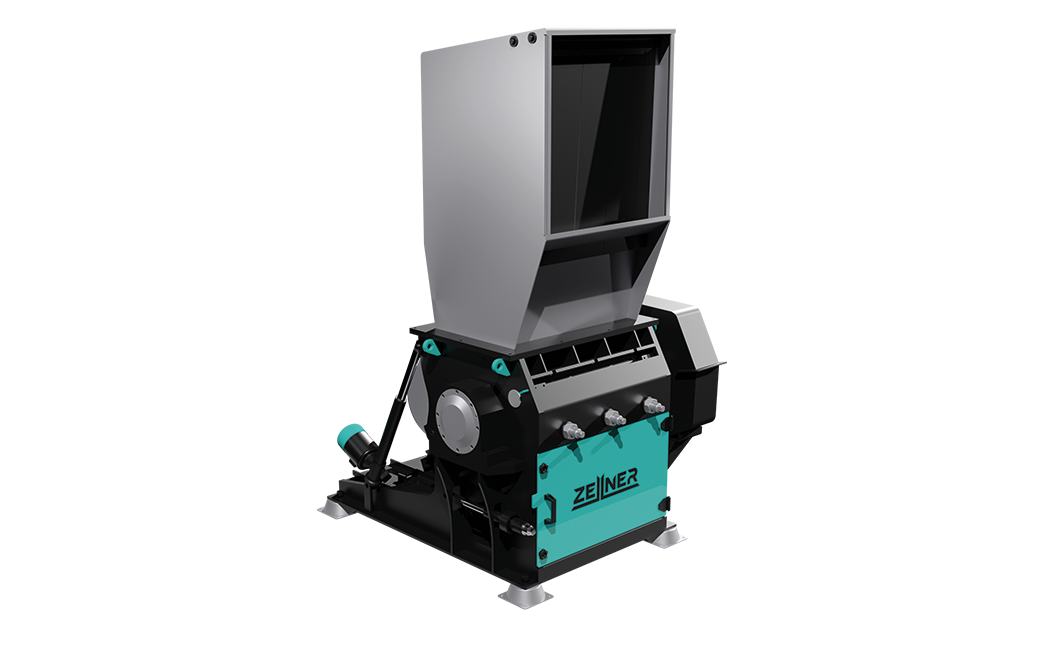

Series ZV

Single Shaft Shredders

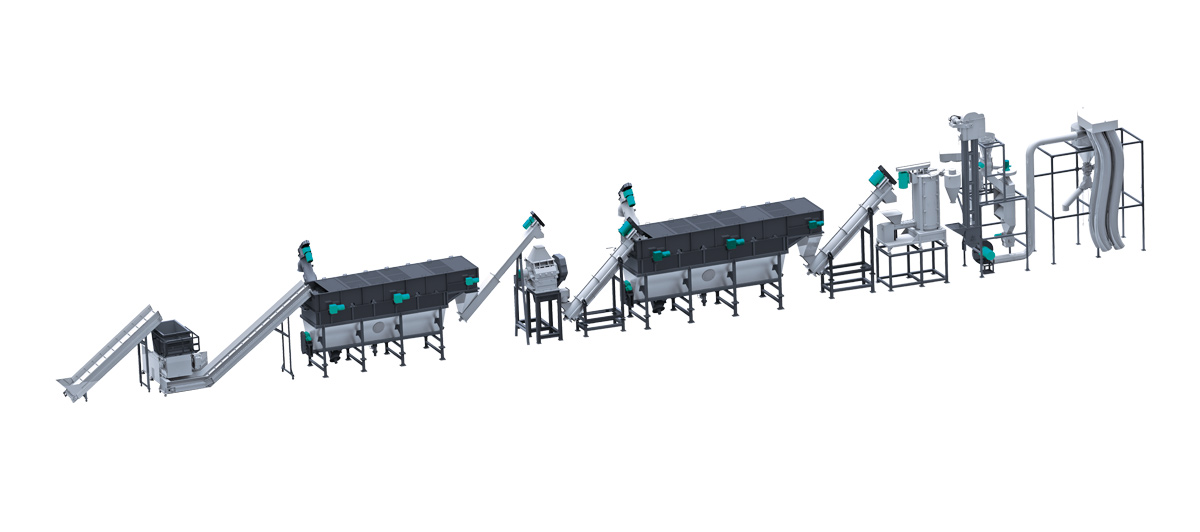

ZV Series Single Shaft Shredders are small - medium size reduction machines suitable for processing a wide range of materials to a uniform particle size. The output products created can often be sold as is, or be sent for further processing through additional equipment (granulators briquetters etc). Throughputs typically range between 300kg/hr – 5,000kg/hr+ depending on the machine model, material type, screen size and application.