Granulator series ZGXC

Granulators

ZGXC Series Heavy Duty Granulators with power ratings of 55kw to 315kw are designed for high throughput processing. With a variety of rotor configurations available, these granulators have a wide range of applications including; hollow and voluminous materials (i.e. plastic drums, crates and chairs), flexible materials such as films, woven bags and rubber, tougher materials such as profiles, thick sheets, and other general plastics.

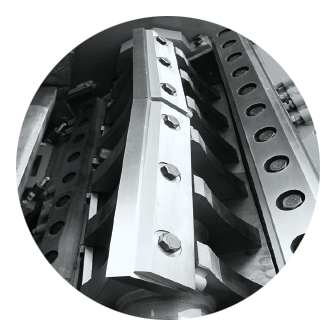

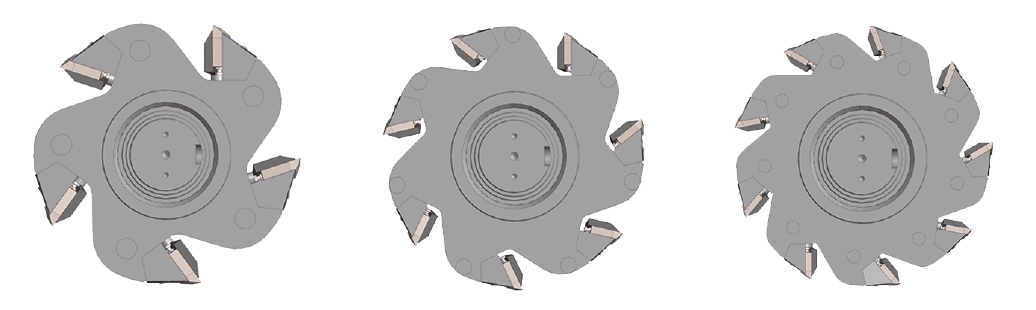

Configurable Rotor Blade Rows

The large diameter rotors of the ZGXC series machines are available with a choice of 5, 7 or 9 rows of rotor blades to suit the specific application. They can therefore achieve the ideal combination of power and cutting eficiency, thus ensuring high throughput volumes and top quality granulated products.

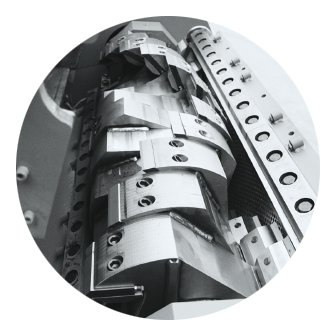

V-Rotor

Our standard open V-Rotor with forward set blades is suitable for processing most types of material. The V-cutting (chevron) configuration of the forward set blades creates a highly eficient, double shear, scissor cutting action.

VB-Rotor

The VB-Rotor with rear set blades is intended for lighter duty applications. The greater shear angle achieved by mounting the blade behind the blade holder results in better performance when processing flexible materials such as plastic films.

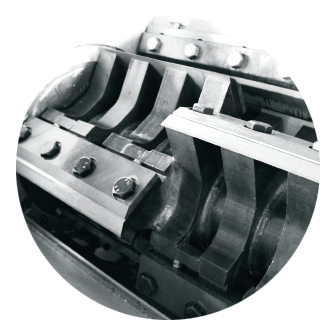

C-Rotor

The C-Rotor is a heavy duty, high inertia, semi-closed shaft design which creates a cascade cutting efect. This rotor design is ideal for processing particularly hard or thicker materials, but is also well suited to processing profiles.

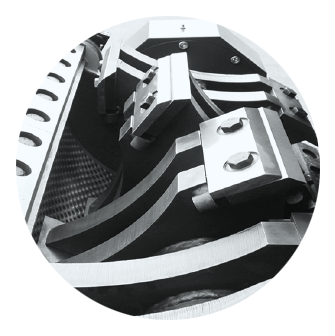

CS-Rotor

The CS-Rotor is a particularly open rotor design which allows more area for the material to fall into between each of the staggered blades. This rotor is ideal when processing hollow & bulky materials.

GMC-Rotor

The GMC rotor is specially designed for film and winding material. The staggered blades can cut of the material easily. The design of the rotor creates a good air stream go through the chamber, reducing heat build up within the chamber to aid cooling.

Technical specifications

| Model | ZGXC800 | ZGXC1200 | ZGXC1200T | ZGXC1600T | ZGXC1200G | ZGXC1600G | ZGXC2000G |

|---|---|---|---|---|---|---|---|

| Dimensions (L × W × H) (mm) | 2165 × 1780 × 3090 | 2165 × 2180 × 3090 | 2490 × 2270 × 3330 | 2490 × 2670 × 3330 | 2650 × 2470 × 3900 | 2650 × 2870 × 3900 | 2650 × 3270 × 3900 |

| Hopper Opening (L × H) (mm) | 750 × 820 | 1150 × 820 | 1150 × 1020 | 1550 × 1020 | 1160 × 1150 | 1560 × 1150 | 1960 × 1150 |

| Rotation Diameter (mm) | Ø 520 | Ø 520 | Ø 660 | Ø 660 | Ø 800 | Ø 800 | Ø 800 |

| Operation Length (mm) | 800 | 1200 | 1200 | 1600 | 1200 | 1600 | 2000 |

| Rotation Speed (RPM) | 520 | 520 | 520 | 520 | 480 | 480 | 480 |

| Screen Size (mm) | Ø 12 | Ø 12 | Ø 12 | Ø 12 | Ø 12 | Ø 12 | Ø 12 |

| Number of Rotor Knives (pcs) | 5×2 | 5×2 | 7×2 | 7×4 | 9×2 | 9×4 | 9×4 |

| Number of Counter Knives (pcs) | 3×1 | 3×2 | 3×2 | 3×2 | 3×2 | 3×2 | 3×4 |

| Main Drive (kW) | 55~75 | 75~90 | 90~132 | 110~160 | 110~160 | 160~250 | 250~315 |

| Hydraulic Power Pack (kW) | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

| Weight (kg) | Approx 4400 | Approx 5500 | Approx 7250 | Approx 8500 | Approx 9300 | Approx 11800 | Approx 15500 |