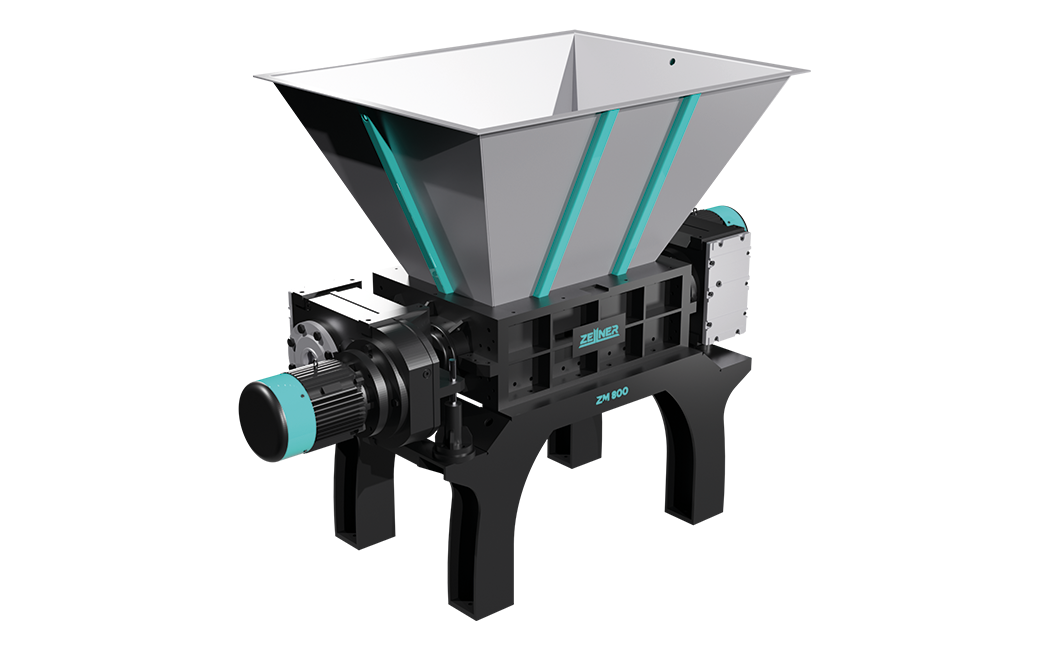

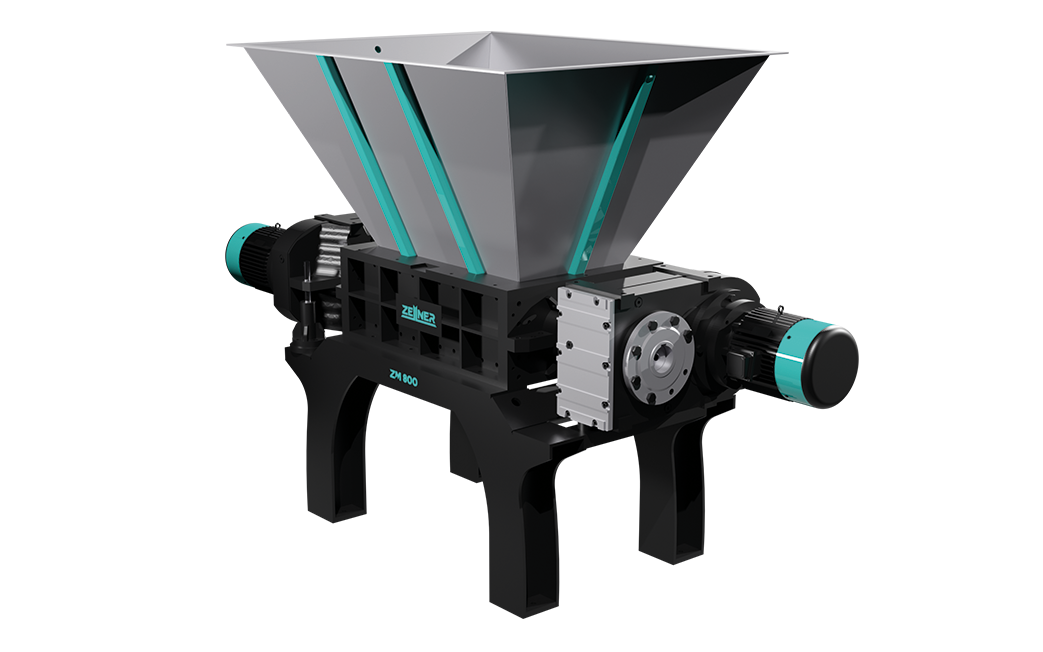

Series ZM

Two-Shaft Shredders

Low speed, high torque operation minimises noise and power consumption, whilst achieving high throughput rates. These machines are particularly suited to the size reduction of bulky or voluminous materials which could include contamination such as metals or stones.

Rotary Screen

To effectively control the output product size, a circular screen mounted around the cutting chamber is the ideal solution. The rotary screen runs at low speed, the oversized fractions are recirculated back to the cutting chamber for further shredding, whilst the sized fraction falls through the screen to the next process.

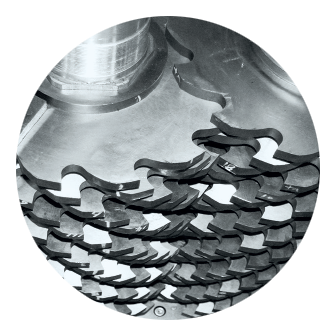

Blade Hook Design

Blade hook designs can be selected according to the nature of the materials being processed. The length of the output material fractions can be controlled by the number of hooks. Experienced selection of the blade hook profile and quantity is of prime importance.

Blade Configuration & Width

Blade profile and width can be specified to suit the type of materials being processed. The width of the output material fractions can be controlled by the thickness of blades. Careful selection of the blade configuration and width is recommended to ensure optimum shredder performance.

Segmented Blades

The segmented blade design can greatly reduce the blade changing time and cost. The blade comprises of the blade holder, and two types of blade segments, with and without hooks. Worn blade segments can quickly and easily be removed and replaced by simply removing the securing screws. No need to remove blade holders from the shafts results in simplified maintenance and reduced downtime. Various blade configurations, hook profiles and widths available.

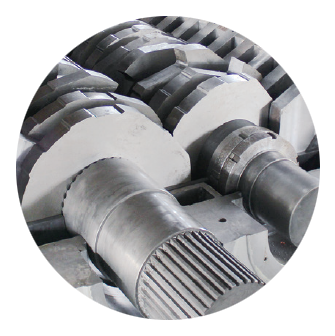

Splined Drive Shafts

Hexagonal shafts are still considered by many to be an effective design, and if it wasn’t for the wear and maintenance problems caused by loose blades rocking on the shafts, particularly in demanding applications with frequent reversals, they would still be preferred by many users. We have resolved theses issues caused by loose blades with our splined shaft design, which securely locks blades and spacers on the drive shafts, eliminating blade rocking and prolonging shaft life.

Hydraulic Force Feeder

A hydraulic force feeder is available to actively press the input material down into the cutting zone between the two shearing shafts. This holding action prevents material from riding over the blade hooks, thus greatly improving the cutting effciency and throughput of the machine. The thoughtful, modular design of the feeder and associated hydraulic power unit provides unhindered access during maintenance, simplifying routine hydraulic oil changes and other maintenance tasks.

Technical specifications

| Model | ZM400 | ZM800 | ZM1200 |

|---|---|---|---|

| Dimensions (L × W × H) (mm) | 1600 × 1225 × 1850 | 2710 × 1270 × 1850 | 3580 × 1965 × 2200 |

| Hopper Opening (L × H) (mm) | 400 × 480 | 800 × 480 | 1200 × 725 |

| Discharge Height (mm) | 600 | 640 | 875 |

| Rotation Diameter (mm) | Ø 276 | Ø 276 | Ø 430 |

| Rotation Speed (RPM) | 13 / 7.7 | 14 | 15 |

| Number of Blades (pcs) | 10 + 10 | 20 + 20 | 15 + 15 |

| Blade Width (mm) | 20 | 20 | 40 |

| Main Drive (kW) | 7.5 | 7.5 + 7.5 | 22 + 22 |

| Hopper Volume (L) | 550 | 750 | 1360 |

| Weight (kg) | Approx 1470 | Approx 2300 | Approx 5120 |